Complete overhaul of die press manufacturing process for a local Evanston machine shop

Northwestern Mechanical Engineering assigned my team of 7 engineers to work with Ward Manufacturing, a manufacturing shop in Evanston, IL. Our task was to analyze and improve their die-press manufacturing process.

I was voted as the Project Lead for both quarters, managing schedule, individual workloads, and technical direction. I also led the prototyping and solution development tasks.

Ward faced several challenges regarding efficiency and precision. After several weeks of observation, user interviews, and data collection & analysis, my team targeted the die installation process as the key area for improvement in both time and precision. Improving installation precision would then impact downtime throughout the manufacturing process due to material changing and quality control.

Our final solution was a holistic change in the operation of the die press including:

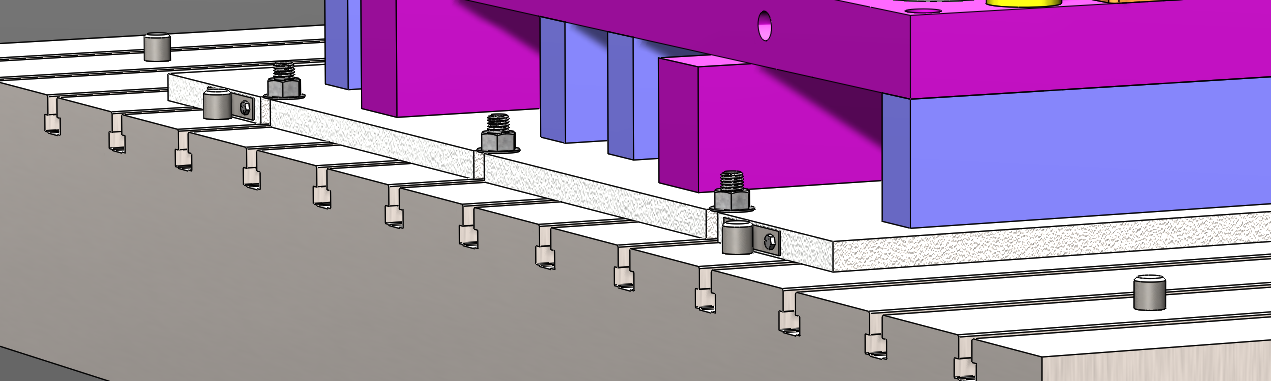

refitting all dies to uniform bases for precise location and faster die securement

drilling into die press and installing replaceable locating pins

accounting for wear with secure, replaceable shims to prevent wear on permanent features

training operators to recognize problems at the source and problem-solve independently